Description

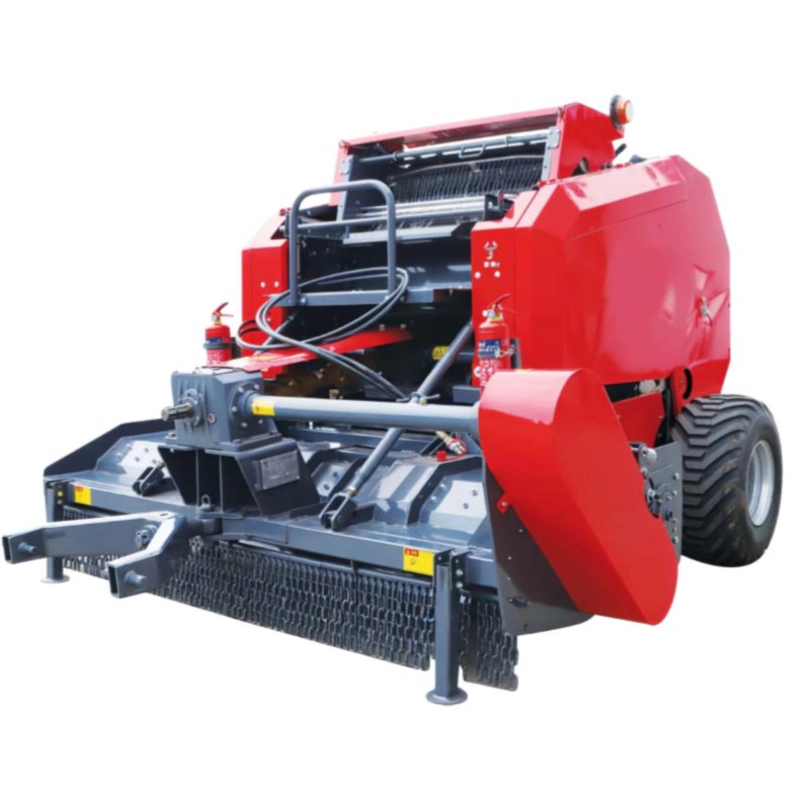

The 9YG-1.0C round baler is a revolutionary product we developed to address the challenge of collecting standing corn stalks. The biggest highlight of this professional standing corn stalk baler is its hammer-claw type pickup, which enables direct collection and baling of standing corn stalks in the field. This completely eliminates the tedious process of first cutting and then laying the stalks, significantly reducing operating costs for users and providing the ultimate solution for improving corn stalk recycling efficiency.

Technical parameters of 9YG-1.0C round baler

Core Technology Highlights

Interchangeable Pickup System:

The 9YG-1.0C round baler allows for quick interchange between a hammer-claw pickup and a toothed pickup. The hammer-claw pickup, specifically designed for corn stalks, powerfully and efficiently feeds upright corn stalks into the machine, fundamentally changing the traditional stalk collection process.

Heavy-Duty Compression System:

The front and rear compartments of the machine utilize dual-sided 16A heavy-duty chains, significantly increasing compression pressure. This results in denser, more compact bales produced by the 9YG-1.0C round baler, with a stable weight of 200-400 catties per bale, perfectly meeting the stringent requirements for bale density during transportation and storage.

Intelligent Control System:

The standard sensor-controlled bale density system ensures precise control within the range of 115-200 kg/m³, guaranteeing uniform quality for every bale.

Core Product Advantages

Advantage 1: Revolutionary Simplified Operation Process

Value: As a professional corn stalk baler, its hammer-claw pickup can directly process upright corn stalks, saving users at least one step in the process and directly reducing the total cost of stalk collection by up to 30%.

Advantage 2: Robust Bale Density and Weight

Value: The immense compression force provided by the dual-sided 16A heavy-duty chains enables this stalk baler to produce bales weighing up to 400 catties, greatly improving transportation and storage efficiency.

Advantage 3: Powerful Power Adaptability

Value: Recommended for pairing with a tractor of 95 horsepower or higher, ensuring ample power even under harsh working conditions. The heavy-duty structural design guarantees the excellent durability of this 9YG-1.0C round baler under long-term high-load operation.

Authoritative Certification and Commitment

Authoritative R&D and Manufacturing Background:

The 9YG-1.0C round baler is developed and manufactured by a national high-tech enterprise certified by ISO9001 quality management system. The entire production process, from raw material procurement and precision machining to complete machine assembly, is under strict international standardized quality control, ensuring the superior performance and reliability of the equipment.

Specific After-Sales Service Commitment:

1. Extended Warranty for Core Components: We provide an extended warranty of 2 years or 1500 working hours for the core transmission assembly (including gearbox and main shaft) of every 9YG-1.0C round baler, reflecting our absolute confidence in the product’s inherent quality.

2. Rapid Response Service Network: Relying on over 120 authorized service outlets nationwide, we promise to provide a clear solution within 2 hours of receiving a repair request and ensure troubleshooting is completed within 48 hours (72 hours for remote areas), maximizing your support during busy agricultural seasons.

3. Spare Parts Supply Guarantee System: We guarantee that over 90% of the commonly used spare parts for the 9YG-1.0C round baler can be shipped from our central warehouse within 24 hours. Furthermore, we solemnly promise that even if the product is upgraded in the future, we will continue to supply a full range of spare parts for this model for no less than 8 years, completely eliminating your worries.

4. Professional Technical Training Support: Purchase includes free online operation and maintenance training, and you can schedule on-site guidance from senior engineers. We can also hold specialized technical training courses for large clients upon request, ensuring your team can maximize equipment efficiency.

Our Solemn Commitment:

We sell not only a high-quality round baler, but also a long-term commitment to “worry-free and efficient” cooperation. Your production efficiency and business profits are our ultimate goal and highest pursuit.

Comparative analysis of products in the same industry

| Core Functions | ||

|---|---|---|

| Comparison Item | 9YG-1.0C Round Baler | Market Competitors |

| Pickup Type |

✓ Hammer Claw/Spring Tooth Interchangeable

|

✗ Fixed Spring Tooth Type

|

| Operation Process |

✓ Direct collection of standing stalks, eliminates swathing

|

✗ Requires cutting and swathing before pickup

|

| Compression System |

✓ Bilateral 16A heavy-duty chains, higher compression pressure

|

✗ Ordinary unilateral chains or belt drive

|

| Technical Configuration | ||

| Required Power |

✓ ≥69.8kW/95hp

|

✗ Usually ≥48kW

|

| Bale Density |

✓ 115-200kg/m³

|

✗ Usually 80-150kg/m³

|

| Operation Results | ||

| Single Bale Weight |

✓ 200-400 jin (100-200kg)

|

✗ Usually 150-300 jin (75-150kg)

|

Frequently Asked Questions (FAQ)

Q1: What are the advantages of a hammer-claw pickup compared to a regular spring-tooth pickup?

A: The hammer-claw pickup is specifically designed for handling upright corn stalks. Its unique hammer-claw structure powerfully grips and feeds upright stalks, preventing tangling and clogging. Compared to a regular spring-tooth pickup, it increases efficiency by approximately 40%, making it particularly suitable for collecting high-yield corn stalks.

Q2: How long does it take to switch from a spring-tooth to a hammer-claw pickup?

A: Switching between the two types of pickups is very convenient. Experienced operators can complete the entire switchover within 30 minutes. The equipment features a quick-connect interface, allowing for switching without special tools.

Q3: What precautions should be taken when handling high-moisture corn stalks?

A: It is recommended to reduce the operating speed to 5-10 km/h and lower the bale density setting by one level. Also, clean the machine’s internal components promptly after use to prevent mold and corrosion.

Q4: What is the maintenance cycle for the dual-sided 16A heavy-duty chains? A: It is recommended to check the chain tension every 50 hours of operation and perform lubrication maintenance every 200 hours of operation. In harsh working environments, the maintenance cycle should be shortened appropriately.

Q5: Is the 95hp tractor (matched) with the equipment sufficient?

A: Absolutely sufficient. The ≥69.8kW/95hp power output is a rigorously tested optimal configuration, ensuring both operational efficiency and avoiding power waste. Under normal operating conditions, the power reserve is ample.

Q6: How to adjust for uneven bale density?

A: First, check if the sensors are clean, then calibrate the density via the control panel. If the problem persists, it is recommended to contact after-sales service personnel for professional adjustment.

Q7: What is the maximum operating slope of the equipment?

A: The equipment can operate normally on slopes ≤15°. When operating on steeper terrain, it is recommended to reduce the speed appropriately to ensure operational safety.

Q8: How to troubleshoot a malfunction in the netting system? A: You can troubleshoot using the following steps: 1) Check if the netting rope is used up; 2) Check if there are any obstructions in the netting rope path; 3) Restart the netting system controller. If the problem persists, please contact technical service personnel.

Q9: What precautions should be taken when storing equipment for an extended period?

A: Before long-term storage, you should: 1) Thoroughly clean the inside and outside of the equipment; 2) Maintain all lubrication points; 3) Park the equipment on a flat, dry surface; 4) It is recommended to cover it with a rainproof cloth for protection.

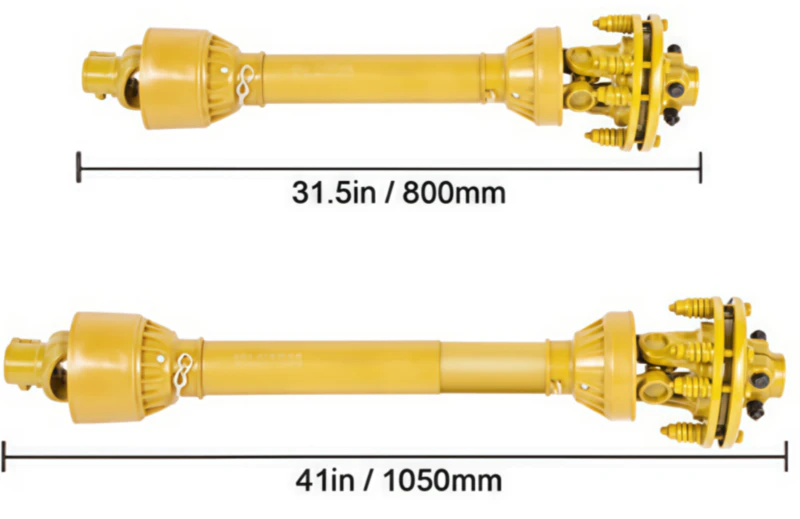

Related product – PTO shaft

Product Relevance:

As the core power transmission component connecting the tractor and the 9YG-1.0C round baler, its reliability directly determines the equipment’s performance.

Core Advantages:

1. Precise Power Matching: Designed specifically for transmitting ≥69.8kW of power, perfectly matching the equipment’s power requirements.

2. High-Strength Materials: Constructed from 42CrMo alloy steel, increasing torsional strength by 50%.

3. Precision Dynamic Balancing: Tested at 2500rpm to ensure stable high-speed operation.

4. Comprehensive Safety Protection: Equipped with a 1.5mm thickened protective cover, meeting European safety standards.

Compatibility Range:

Power Compatibility: 69.8-110kW (95-150hp)

Speed Matching: Standard speed 540 rpm

Spline Specification: 6-key/21-key standard spline interface

Recommended Compatible Models:

1. Dongfanghong Series: LX904/LX1004/LX1204

2. Lovol Heavy Industry: M904-Q/M1104-Q

3. John Deere: 5E-954/6B-1054

4. CNH: MX100/MX110

User Value:

1.Ensures power transmission efficiency exceeding 95%

2.Effectively prevents equipment damage caused by torque fluctuations

3.Provides reliable safety for high-intensity operations

Purchase Tips: Please provide your tractor model and power when purchasing, and we will recommend a fully matched driveshaft model for you. More technical parameters can be found in the agricultural machinery professional database.

We sell more than just the 9YG-1.0 round baler; we sell a guarantee of consistently high yields. Your productivity is our top priority. If you are facing agricultural challenges or considering purchasing a forage baler, please feel free to contact us.

Editor: WLB

Reviews

There are no reviews yet.