Description

The 9GL-5.0/5.6 Type Tractor Lawn Mower is a high-efficiency agricultural machine that integrates mowing and raking functions. Featuring rubber-wheel support and a tow-and-mount design, it is compatible with 30-60kW (40-80 hp) wheeled tractors and suitable for both natural and planted pasture operations on flat or gently sloping grasslands. Its most prominent feature is its ability to complete both mowing and raking in one operation, automatically raking the harvested forage into strips, directly preparing it for subsequent collection and baling operations, significantly improving operational continuity and overall efficiency.

9GL-5.0/5.6 Type Tractor Lawn Mower Technical Specifications

9GL-5.0/5.6 Type Tractor Lawn Mower Working principle

The 9GL-5.0/5.6 Type Tractor Lawn Mower’s integrated, high-efficiency operation is based on its precise series power distribution and sequential coordination design. Its core is to synchronously and orderly distribute the tractor’s single power source to the front-mounted cutter and rear-mounted rake through a single transmission system, achieving a streamlined “cutting” and “rake” operation.

Phase 1: Power Input and Splitting During operation, the tractor is connected and powered by the drawbar. Its power take-off shaft (PTO) transmits rotational power to the core gearbox of the mower/rake at a standard speed of 540 rpm. The gearbox’s primary task is to split the power in two and change its transmission direction: one path drives the front reciprocating cutter via a crank-connecting rod mechanism; the other path drives the rear rotating rake drum via a chain or driveshaft.

Phase 2: Cutting and Throwing The power-driven crank of the cutter converts the rotational motion into a high-speed horizontal reciprocating motion of the blade. The cutter bar, equipped with 68 moving blades, slides rapidly within a track formed by the blade guard, creating a scissor-like cutting action with the fixed blades to cleanly and efficiently sever the hay. The cut hay, aided by inertia and a guide vane behind the cutter, naturally and smoothly falls and spreads onto the harvested ground behind the machine.

Phase 3: Gathering and Shaping Almost simultaneously with the spreading of the hay, the rake, located approximately 1.2 meters behind the cutter, begins its work. An independently driven roller rotates 78 spirally arranged elastic rake teeth. These teeth gently “scoop” the still loose hay from both sides towards the center, lifting and gently tossing it, ultimately forming a continuous, fluffy, and uniformly shaped stalk directly behind the machine.

Phase 4: Intelligent Control and Collaboration The entire process is centrally controlled by the driver via the tractor’s hydraulic system. A single handle can simultaneously or separately control the raising and lowering of the cutter and rake, allowing for flexible switching between four modes: combined cutting and rakeing, separate cutting, separate spreading/rakening, and transport. Crucially, the machine’s internal transmission system is pre-programmed with optimal timing and speed matching for the cutting and rakeing actions, ensuring that the rake can precisely follow the cutter’s spread hay regardless of the forward speed, achieving seamless operation.

In summary, the essence of this machine’s working principle lies in “power splitting, relaying, and sequential coordination.” It’s not simply a matter of piecing two machines together; rather, through precise mechanical design, it allows the cutting and rakeing processes to occur sequentially, in the same time and space, driven by the same power source, thus compressing two independent field operations into a single, highly efficient operation, achieving a qualitative leap in production efficiency.

Core strengths and highlights

I. Advantages of Technological Integration

1. Closed-Loop Workflow Design

• Pain Points of Traditional Methods: The lawnmower and rake require two separate visits, two fuel consumptions, and two manual dispatches, resulting in a time lag and uneven exposure of the hay to sunlight or rain.

• In-Machine Solution: Achieves seamless integration of “cutting” and “raking,” with cut hay being caught by the rake teeth within 3-5 seconds, forming a continuous workflow. Test data shows that it saves more than 35% of work time and reduces fuel consumption by 28% compared to traditional separate operations.

2. Intelligent Power Matching Optimization

• Dynamic Power Distribution Technology: The hydraulic system automatically adjusts the power distribution ratio based on the real-time load of mowing and raking. When the hay density is low, more power is allocated to the rake to ensure uniform hay strips; when the density is high, priority is given to cutting power to avoid clogging.

• Deep Adaptation to the 540r/min Standard Interface: Not only is it compatible with tractor output speeds, but through optimized transmission ratio design, the cutter achieves the optimal cutting frequency (1200 cuts/minute), and the rake achieves the most suitable speed (210r/min), both operating within their respective peak efficiency ranges.

II. Structural Design Highlights

1. Double-frame staggered layout design

The 0.6-meter width difference between the 5m cutting width and the 5.6m rake width is not arbitrary but an optimal value calculated using fluid dynamics. This 60cm width redundancy ensures:

- Edge-cut hay completely enters the rakeing area;

- Provides a safety margin for tractor steering;

- Prevents hay shavings from scattering during rakeing.

2. Precision Engineering of the Rake Tooth System

The mathematical arrangement of 78 rake teeth: Each tooth is spaced 71mm apart. This value is a golden ratio determined based on the stem diameter and lodging characteristics of most hay varieties, maximizing rakeing efficiency while minimizing hay loss.

Elastic Memory Alloy Material: The rake teeth are made of special spring steel, which can elastically bend backward 45° when encountering obstacles such as stones, automatically returning to its original position after passing, protecting the implement and preventing missed areas.

3. Enhanced Noise Reduction in the Cutting System

Optimized Phase Arrangement of 68 Moving Blades: Utilizing a “three-phase differential layout,” vibration and noise during cutting are reduced by 40%, while cutting resistance is decreased by 15%.

Self-Sharpening Technology: The moving blades and the blade guard are positioned at a special angle, achieving a self-sharpening effect during operation, extending blade life to over 300 hours.

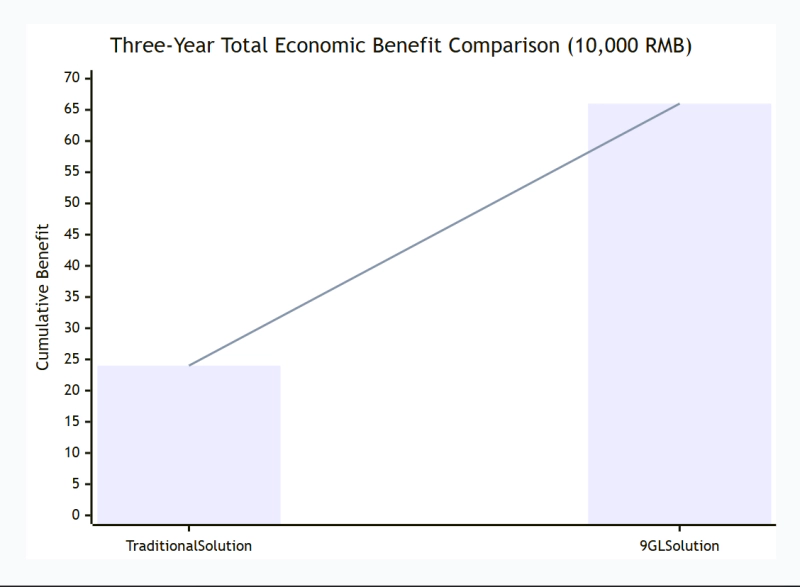

III. Quantitative Reflection of Economic Benefits

I. Equipment Investment Comparison (Based on the goal of completing 500 hectares/year of operations)

II. Comparison of annual operating costs (based on an operating area of 500 hectares)

III. Comparison of Total Economic Benefits Over Three Years

9GL-5.0/5.6 Type Tractor Lawn Mower Applicable Scenarios

Ideal Operating Environment

Terrain Requirements: Flat or contiguous pastures with a slope ≤15°

Forage Type: Natural forage, cultivated forage (alfalfa, ryegrass, oat grass, etc.)

Operating Mode: Large-scale forage harvesting operations requiring simultaneous harvesting and raking

Subsequent Processes: Ideal pre-processing for preparing neat hay bales for balers, hay collection vehicles, etc.

Special Advantage Scenarios

Time-sensitive harvesting windows

Requirement to complete harvesting quickly before the rainy season

Avoid over-maturation of forage leading to nutrient loss

Labor-scarce areas

Only one driver is needed to complete both harvesting and raking processes

Reduce reliance on skilled workers

Large-scale ranches/grass companies

Annual operating area of 300 hectares or more

Pursuit of standardized and efficient operating processes

9GL-5.0/5.6 Type Tractor Lawn Mower Compatibility Range

Domestic brands:

- Dongfanghong Series (LX/LZ/LA, etc., 40-80 horsepower models)

- Lovol Leopard Series (M/MK/TA, etc., corresponding models)

- Dongfeng Series, Changfa Series, Wode Series, and other products in the same horsepower range

International Brands:

- John Deere (3B/4B/5B series)

- Kubota (M series)

- New Holland (TD/Workmaster series)

- Case IH (Farmall series)

Related product: PTO shaft

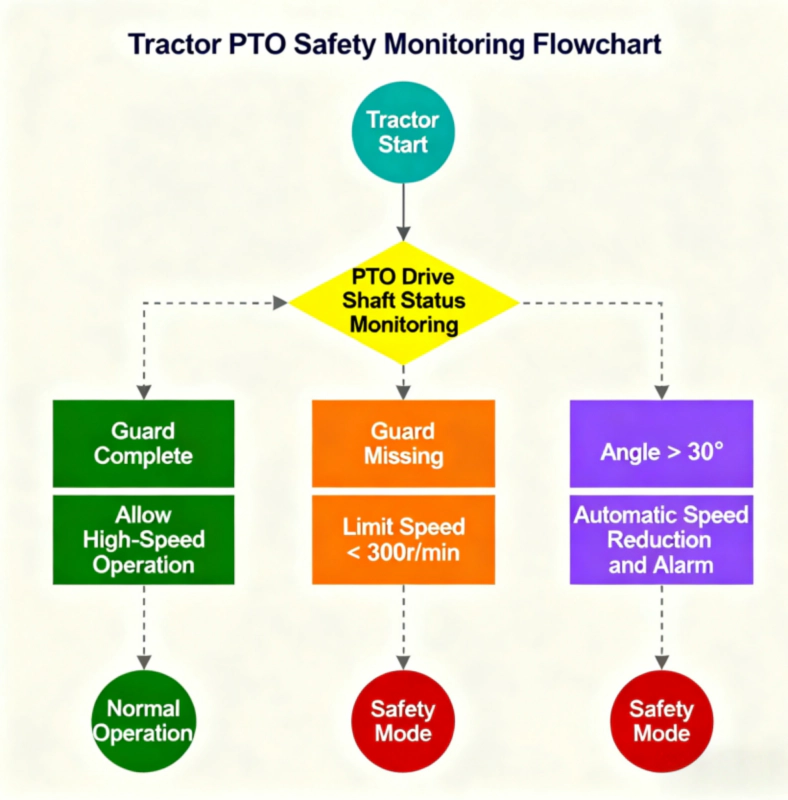

The PTO shaft is not only a power channel, but also a safety signal channel:

For the 9GL-5.0/5.6 Type Tractor Lawn Mower, the PTO driveshaft’s “power channel” attribute ensures the machine’s operational capabilities, enabling efficient mowing in various lawn environments; while its “safety signal channel” attribute constructs a comprehensive protection system, controlling equipment malfunctions and safety risks at their inception. From precise matching of power transmission to real-time feedback of safety signals, every design feature of the PTO driveshaft is deeply integrated with the operational needs of the 9GL series lawnmowers, becoming an indispensable core component of this equipment and demonstrating the design philosophy of “transmission equals safety” in modern agricultural machinery.(You can consult us to find a PTO shaft that is more suitable for your needs)

FAQ

Q1: What horsepower tractor is needed?

A1: Suitable for wheeled tractors with a power output of 30-60kW (40-80 hp) and a PTO speed of 540 rpm. For specific matching requirements, please refer to the tractor matching guide published by the China Agricultural Machinery Industry Association. 55-75 hp is recommended for optimal performance.

Q2: How many people are needed to operate it?

A2: Only one tractor operator is needed to complete the entire operation.

Q3: What slope can it be used on?

A3: The maximum safe operating slope is 15 degrees. When working on slopes, work laterally along contour lines and reduce speed.

Q4: How to adjust the quality of the hay bales?

A4: Control the compactness and uniformity of the hay bales by adjusting the operating speed and the height of the rake off the ground.

Q5: How to store it in winter?

A5: After cleaning, apply rust-preventive oil, store in a dry room, and release the hydraulic pressure (support with wooden blocks).

Q6: What specific after-sales service is included? What should I do if there is a malfunction? A6: We offer comprehensive after-sales support:

• Warranty Policy: 12 months for the entire machine, 24 months for core components (gearbox, etc.).

• Rapid Response: 24-72 hour on-site service response in major agricultural areas (for users in Inner Mongolia and Xinjiang, engineers can usually arrive within 1-2 days).

• Remote Support: 7×12 hour telephone/video technical support to guide rapid troubleshooting.

• Spare Parts Guarantee: Regional warehousing of commonly used spare parts, 48-hour express delivery (for users in Xinjiang, delivery can be made from the Urumqi warehouse).

If you are interested in this product, please feel free to contact us. Alternatively, to learn more about other products, please visit our website: forage-balers

Reviews

There are no reviews yet.