Description

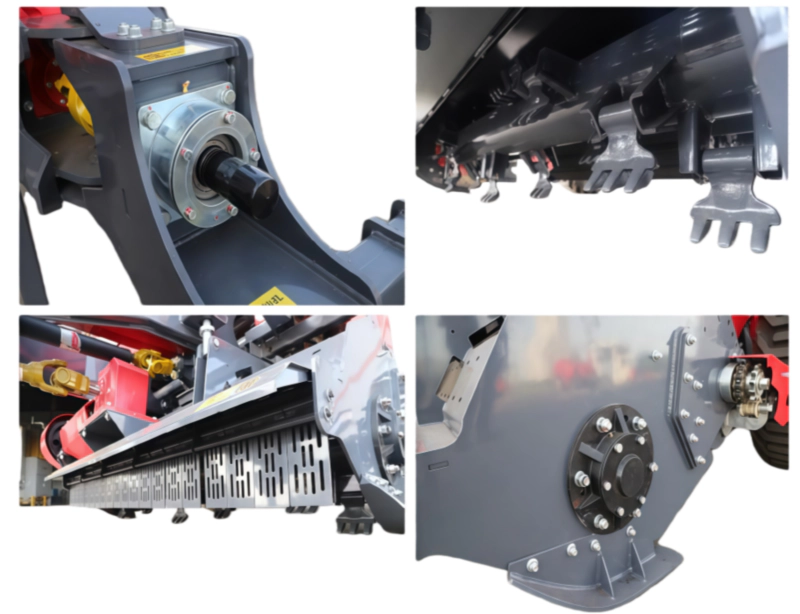

The 9YG-1.25 round baler features a traction-type hook-and-loop design with a pickup width of 2240mm. Equipped with a spring-tooth pickup, it can efficiently collect various crop straws and forage. Its feeding system uses an auger + toothed roller + drum structure to ensure even and smooth feeding. The compression chamber is a drum-type structure, 1250mm wide and 1200mm in diameter, equipped with 18 compression rollers, resulting in fast and dense bale formation. The entire machine features automatic netting, simple operation, and secure baling.

9YG-1.25 Round Baler Technical Specifications

9YG-1.25 Round Baler Working principle

The 9YG-1.25 Round Baler operates as a highly efficient, continuous, and automated process. Its core function is to transform loose materials into high-density standard bales. The specific working principle is as follows:

1. Pick-up and Feeding Stage

A tractor pulls the 9YG-1.25 Round Baler forward. Crops (such as hay and straw) spread on the ground are picked up wide by a toothed pick-up device. The pick-up device rotates, throwing the material backward and upward into the feeding system.

The material is first collected and initially compressed by a transverse auger and evenly conveyed to the center. Then, toothed rollers grab and lift the material, finally feeding it into the compression chamber inlet composed of multiple rollers. This combination of auger and toothed rollers ensures that the material enters the core working area smoothly, evenly, and without blockage.

2. Rolling and Forming Stage

The material enters an annular compression chamber composed of 18 rolling rollers. Driven by the powerful PTO transmission of the tractor, these rollers begin to rotate in the same direction, like a rolling conveyor belt, causing the material to continuously tumble within the compression chamber.

During this process, the material is continuously sucked in, stacked, and compressed. As more material is continuously fed in, the internal straw core grows larger, the compression force increases accordingly, and the bale density gradually increases. Sensors monitor pressure changes within the compression chamber in real time and automatically adjust via the hydraulic system to ensure the bale density remains stable within the preset range of 100-200 kg/m³.

3. Baling and Unbaling Stage

When the bale grows to the predetermined size (approximately 1300 mm in diameter), the system triggers the fully automatic baling mechanism. The baler automatically wraps a special baling net around the outer surface of the formed bale. The spacing and tension of the net are precisely controlled by the system to ensure a secure baling.

After baling, the rear door of the compression chamber opens automatically under hydraulic control, and the formed and baled bale is smoothly unloaded onto the ground. Subsequently, the door closes automatically, and the equipment immediately enters the next work cycle, achieving continuous operation.

Core Product Advantages

1. Bale Forming Advantages:

The 9YG-1.25 Round Baler employs an 18-roll pressure roller and sensor-linked density control system, consistently producing high-quality bales with a density of 100-200 kg/m³. The bales formed by this round baler have a tight core and uniform shape. Compared to traditional models, their shape retention rate during long-distance transportation and open-air stacking is improved by over 30%, significantly reducing material loss.

2. High-Efficiency Operation Advantages:

Equipped with a 2240mm ultra-wide spring tooth pickup, this Round Baler has a larger coverage area per operation. Combined with an operating speed of 5-35 km/h, it maintains a peak operating efficiency of up to 100 bales/hour in various terrain conditions, including hilly and plain areas, ensuring users can complete large-scale harvesting tasks within short agricultural time windows.

3. Intelligent Advantages:

The integrated fully automatic netting system is the core automation feature of the 9YG-1.25 Round Baler, requiring no manual intervention from bale formation to binding. Its intelligent control system automatically matches the winding and pressing speed according to the feed rate, effectively avoiding blockages or loosening caused by uneven feeding, and significantly reducing the operator’s labor intensity and technical threshold.

4. Reliability Advantages:

As a towed round baler, its 4060kg structural weight stems from the reinforced design of key load-bearing components. The compression chamber rollers and transmission system are optimized for continuous high-intensity operating environments, with a mean time between failures (MTBF) far exceeding the industry average, ensuring the equipment’s uptime and service life under harsh working conditions.

Comparison of products with the same industry

Customer feedback

“Our cooperative purchased two 9YG-1.25 Round Balers last year. What we’re most satisfied with is how tightly they produce bales. Before, we used an old-fashioned round baler; the bales were loose, and we could only carry a few at a time, making transportation uneconomical. Now, with this machine, the bale density is much higher, and we can carry almost 30% more bales per truck, reducing the transportation cost per bale. Plus, the automatic netting is very convenient; we don’t need to manually follow it.” — Captain Wang, a large agricultural machinery cooperative in Heilongjiang

“On my farm, this 9YG-1.25 Round Baler has been working efficiently for over 500 hours. Its heavy-duty structure and stable hydraulic system are impressive; even when processing our large alfalfa fields, there have been almost no downtimes. Compared to the brands we used before, this Chinese-made round baler performs exceptionally well in terms of durability and cost-effectiveness.” — John Smith, rancher in New South Wales, Australia

“Our farm has a large planting area, and rain is our biggest fear when harvesting hay.” “This 9YG-1.25 Round Baler is indeed fast, with a wide pick-up width. Driving a high-horsepower tractor along, bales come out one after another. Its efficiency is estimated to be 40% higher than our old machine. Last year, we managed to bale over a thousand acres of hay before the rains, which was a huge help. This round baler is now our main machine.” — Manager Zhang, a pastoral farm in Inner Mongolia

FAQ

Q1: What tractor power is required to power the 9YG-1.25 Round Baler?

A: We recommend a tractor with at least 75kW of power. If the material has high moisture content or if maximum efficiency is required, we recommend a tractor with 90kW or higher to ensure sufficient power, prevent clogging, and extend the equipment’s lifespan.

Q2: Is the bale density of this round baler adjustable?

A: Yes. One of the core advantages of the 9YG-1.25 Round Baler is its sensor-controlled bale density system. Users can set different density levels on the controller according to crop type and storage requirements, and the equipment will automatically adjust the hydraulic pressure to precisely control the density within the range of 100-200 kg/m³.

Q3: Are there any requirements regarding the types of crops the equipment is designed for?

A: It is highly adaptable. This round baler is specifically designed to handle a variety of forages (such as alfalfa and oat hay) and straws (such as wheat, rice, and corn stalks). Its powerful feeding system and roller design can effectively handle a variety of materials, from dry to slightly damp.

Q4: What should I do if the automatic netting system malfunctions?

A: First, the equipment is equipped with automatic alarm functions for when the netting rope runs out or breaks. Most netting problems (such as rope jamming) can be resolved by manually reversing the netting device after stopping the machine. It is recommended that operators familiarize themselves with the emergency handling section of the User Manual. We also provide detailed fault code explanations and remote technical support.

Q5: Is a faster operating speed always better?

A: Not necessarily. Although the 9YG-1.25 Round Baler allows operation at speeds of 5-35 km/h, the optimal speed needs to be adjusted according to the crop yield and moisture content. When the crop yield is high and the moisture content is high, the speed should be appropriately reduced to ensure smooth feeding and bale quality. Blindly pursuing high speeds may lead to feeding blockages or loose bales.

Q6: Is daily maintenance complicated?

A: Easy maintenance is one of its design highlights. Daily maintenance requires only the following:

After daily operation: Clean weeds and dirt from the machine.

Every 8-10 hours of operation: Lubricate all bearings with grease through the centralized lubrication point.

Regular checks: Check the oil levels in the springs, drive belts, and gearbox.

The modular design makes replacing wear parts (such as springs) very easy.

Q7: Is it compatible with my older tractor’s PTO interface?

A: This machine requires a power take-off shaft (PTO) speed of 720 r/min (tractors with 540/1000 rpm require the corresponding speed setting). As long as your tractor’s PTO interface standard (such as 6-key or 21-key spline) matches the speed and power requirement, it can be coupled. If in doubt, please provide your tractor model, and our technical team will confirm for you.

Q8: Approximately how many meters of baling netting are needed for one bale?

A: Based on the bale size (diameter × width: 1300 × 1250 mm) and the default number of wraps, forming one bale requires approximately 25-30 meters of baling netting. The standard baling netting specifications used by the equipment are 1.25 meters wide and 2000 meters long per roll, with one roll capable of forming approximately 65-80 bales.

Related products: PTO drive shafts

To ensure efficient operation of the 9YG-1.25 Round Baler, it is recommended to use a suitable PTO drive shaft (power output shaft). This equipment requires a power output shaft speed of 720 r/min. Please be sure to select a universal joint drive shaft that meets the standards and has stable torque transmission to ensure smooth power transmission and a longer service life.

Hubungi Kami

We provide a comprehensive after-sales service system for each 9YG-1.25 Round Baler, including equipment installation guidance, operation training, regular inspections, and spare parts supply. Please feel free to contact us with any technical questions or purchasing inquiries.

Edit WLB

Reviews

There are no reviews yet.