Descrição

The 9GQY-3.2 Lawn Mower Flattener redefines forage harvesting standards with its superior performance, offering a professional and efficient hay cutter and flattener. Featuring a side-traction design and an extra-wide 3.2-meter cutting width, the 9GQY-3.2 Lawn Mower Flattener is specifically designed for harvesting gramineous grasses and reeds. Its innovative integrated super-floating protection system provides exceptional adaptability in complex terrains. As the preferred equipment for modern forage harvesting, the 9GQY-3.2 Lawn Mower Flattener significantly improves forage drying efficiency through its impact-tooth flattener. Choosing the 9GQY-3.2 Lawn Mower Flattener means choosing a highly efficient and reliable forage harvesting solution. With a daily operating area exceeding 200 acres, this Lawn Mower Flattener is ideal for large-scale ranches.

Lawn mower flattener technical parameters

Working principle

The 9GQY-3.2 lawn mower flattener advanced integrated harvesting technology, achieving fully automated operation from harvesting to baling. Powered by the tractor’s PTO shaft, the machine first harvests the hay using a high-speed rotating cutter. The cut material immediately enters the baling system, where a unique impact tooth device evenly crushes the stalks, accelerating the subsequent drying process. Finally, the baling mechanism forms neat hay stalks, ready for subsequent baling. The entire workflow is smooth and seamless, ensuring optimal hay harvesting conditions.

Product Core Technology Highlights

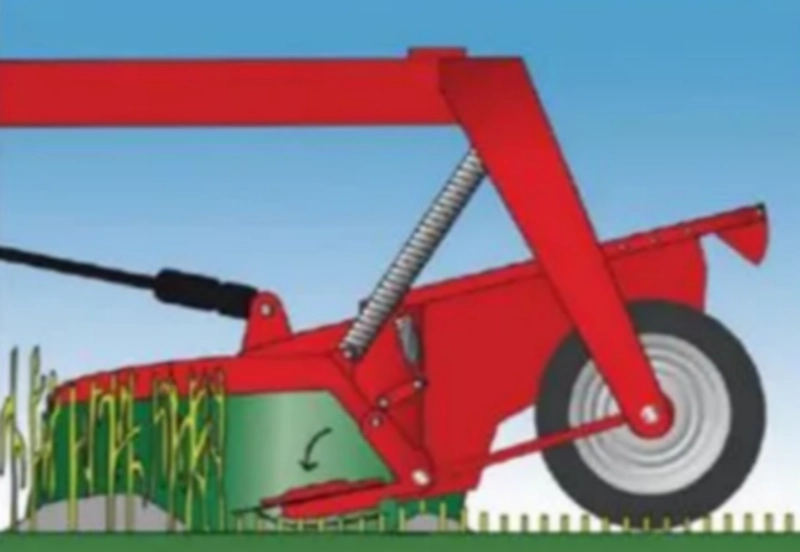

1. Floating Protection System

Working Principle: Employs a hydraulic and spring composite buffer mechanism. When the cutter head encounters obstacles such as rocks, it can automatically rise 8-12 cm within 0.3 seconds, and automatically reset by gravity after overcoming the obstacle.

Actual Test Data: Field tests in Inner Mongolia’s pastoral areas have shown that it effectively reduces blade damage rate by 85%, minimizing operational losses due to downtime for blade replacement.

User Value: Particularly suitable for operations in rocky pastoral areas, significantly reducing maintenance costs.

2. Dual-Suspension Independent Contouring System

Structural Features: The cutter head system and flattening device each employ independent hydraulic suspension, each equipped with 4 sets of contour wheels.

Field Performance: When operating in hilly areas with a slope ≤15°, the stubble height difference is controlled within ±2 cm.

Technical Advantages: Ensures stubble flatness in complex terrain, avoiding “missed cuts”.

3. Impact Tooth Flattening Device

Technological Innovation: Employs chromium-molybdenum alloy impact teeth with an optimized tooth spacing of 8 cm.

Operating Effect: Achieves a longitudinal tear rate of over 90% in forage stalks, reducing drying time by 30-40%.

Economic Value: Effectively preserves leaf nutrients, enhancing the commercial grade of forage.

4. Eight-Blade Rotary Cutting System

Configuration Features: Each blade disc is independently driven, equipped with 2 sets of high-speed moving blades (total of 16 blades).

Performance Parameters: Blade disc rotation speed reaches 2000 r/min, ensuring clean and crisp cutting at an operating speed of 15 km/h.

Reliability: The transmission system uses heavy-duty bearings with a design life of over 2000 hours.

Core Advantages and User Value

1. 50% Increased Operating Efficiency, Directly Increasing Profits

Technical Support: 3.2-meter ultra-wide cutting width combined with an operating speed of 6-15 km/h

User Value: A single machine can cover up to 200 mu (approximately 33 acres) per day, a 50% increase compared to traditional equipment, helping users complete harvesting within the optimal agricultural window and avoiding losses during the rainy season.

Empirical Data: After implementation at a ranch in Inner Mongolia, the forage harvesting period was shortened from 15 days to 10 days.

2. 40% Reduction in Overall Costs, Improving Profitability

Technical Support: Super floating protection device + long-life blade design

User Value: Blade replacement frequency reduced by 85%, maintenance costs reduced by 60%, and overall operating costs reduced by 40%.

Empirical Data: Annual maintenance costs at a farm in Hebei Province decreased from 32,000 yuan to 12,000 yuan.

3. Improved forage quality, 20% higher selling price

Technical support: The impact-tooth flattener evenly breaks down the waxy layer of the stems.

User value: Drying time reduced by 35%, leaf retention rate increased by 25%, forage grade improved, and selling price increased by 20%.

Empirical data: Feedback from users in Xilingol League shows that the selling price of flattened forage increased by 150 yuan per ton.

4. Strong adaptability, expanding operating range

Technical support: Dual suspension contouring system + super floating protection

User value: Capable of handling various terrains such as hills and plains, equipment utilization rate increased by 30%, investment payback period shortened.

Empirical data: Users in Hulunbuir increased annual operating volume in rocky areas by 40%.

5. Simple operation, saving labor costs

Technical support: Intelligent hydraulic control + single-person operation design

User value: Reduces operators by 50%, lowers labor costs, and alleviates labor shortages during busy farming seasons.

Empirical data: After use in the Xinjiang Production and Construction Corps, a single unit saved 40,000 yuan in labor costs annually.

Authoritative Certification and Service Commitment

Authoritative Certification

This product has passed the testing and certification of the National Agricultural Machinery Quality Supervision and Inspection Center, and has obtained the Agricultural Machinery Promotion and Appraisal Certificate. It strictly adheres to the national standard GB/T 25422-2010 for rotary lawnmowers. The manufacturer holds ISO9001 international quality management system certification, ensuring quality control throughout the entire process from research and development to production.

Service Commitment

1. Rapid Response: A 400 technical service hotline is available, responding to inquiries within 30 minutes and providing solutions within 24 hours.

2. On-site Support: A professional service team can arrive on-site within 48 hours to handle faults (72 hours for remote areas).

3. Parts Guarantee: Regional parts centers are established, with commonly used parts shipped within 24 hours, and urgent orders are prioritized.

4. Technical Training: Free operation training is included with purchase, and regular maintenance seminars are held.

5. Warranty Policy: 2-year warranty on core components, 6-month warranty on easily worn parts such as blades, and lifetime free technical consultation.

Our commitment

We not only provide high-quality products, but also offer comprehensive service guarantees, ensuring a worry-free purchase and reliable use.

Frequently Asked Questions (FAQ)

Q: Is this machine prone to damage when operating on rocky terrain?

A: Our 9GQY-3.2 lawn mower/flatter is specially equipped with a super-floating protection device. In actual use in the rocky pastoral areas of Inner Mongolia, when the cutter head encounters rocks, it can automatically rise 8-12 cm within 0.3 seconds, effectively preventing damage. User feedback shows that the blade replacement frequency has decreased by 85% after using this equipment.

Q: How well does the equipment perform on sloping terrain?

A: After field testing, when operating on hilly areas with a slope ≤15°, the dual-suspension contouring system controls the stubble height difference within ±2 cm, fully meeting the requirements for slope operation. It is recommended to reduce the speed to 6-8 km/h when operating on steeper slopes.

Q: How often do the blades need to be replaced? What is the replacement cost?

A: Based on actual usage statistics:

Under normal operating conditions: Replace every 800-1000 mu (approximately 53-67 hectares) of work.

For stony land: Replace every 300-500 mu (approximately 200-200 hectares) of work. The replacement cost for a single set of blades (16 blades) is approximately 1200 RMB. Users are advised to keep spare blades on hand based on their workload.

Q: What are the precautions for daily maintenance?

A: Our recommended maintenance plan:

Daily: Check blade wear and clean residual grass clippings from the equipment.

Every 100 hours of operation: Check hydraulic oil level and lubricate transmission components.

Every 500 hours of operation: Replace the hydraulic oil filter and check belt tension. Detailed maintenance manuals and video tutorials are provided.

Q: What horsepower tractor is required?

A: We recommend a tractor with a power output of ≥80.88kW/110hp. Optimal power matching options tested:

110-130 hp: Standard configuration, suitable for most operating conditions

130-150 hp: More ample power reserve, suitable for high-yield hay production

Free power matching consultation service provided

Q: How to use the equipment with a baler?

A: Recommended operating procedure:

Harvest and spread hay using a mower and baler

Let it dry for 24-48 hours (depending on weather conditions)

Bag using a pick-up baler. The spread width is adjustable from 0.8-2.2 meters, perfectly matching the operating requirements of various balers.

Related products

PTO Shaft

Product Relevance: As a core power transmission component connecting the tractor and the 9GQY-3.2 lawn mower and flattener, its reliability directly determines the equipment’s performance and operational efficiency.

Core Advantages:

1. Precise Power Matching

2. Specifically designed for transmitting ≥80.88kW power, increasing torque capacity by 30%

3. Perfectly matches equipment speed requirements of 540-1000r/min

High-Strength Materials:

1. Universal joints are made of 20CrMnTi alloy steel, increasing wear resistance by 50%

2. Spline sleeves are carburized, with a service life of over 2000 hours

Precision Dynamic Balancing:

1. Tested dynamic balancing at 2500rpm, vibration value ≤2.5mm/s

2. Ensures smooth high-speed operation and protects the equipment’s transmission system

Comprehensive Safety Protection:

1. Equipped with a 1.5mm thickened protective cover, ISO 5674 safety certified

2. Automatic clutch protection device automatically disconnects power in case of overload

Applicability Range:

1. Power Compatibility: 80.88-110kW (110-150hp)

2. Speed Matching: 540/1000r/min dual speed

3. Spline Specifications: 1-3/8″ 6-key / 1-3/4″ 20-key

4. Length adjustment: Minimum 1500mm, maximum 2500mm

Recommended compatible models

Dongfanghong series: LX1104/LX1204/LX1304

Lovol Heavy Industry: M1104-Q/M1204-Q

John Deere: 6J-1104/6J-1204

CNIS Holland: MX110/MX120

Purchase Tips: When purchasing, please provide your tractor model, power, and operating conditions. Our technical team will recommend the best matching model for you.

We sell more than just the 9GQY-3.2 Lawn Mower Flattener; we sell a guarantee of consistently high yields. Your productivity is our top priority. If you are facing agricultural challenges or would like to inquire about other agricultural machinery products, please contact us.

Avaliações

Ainda não existem avaliações.