Description

The 9YG-2.24D Round Baler (S9000 Classic) is a high-performance forage baler designed to meet the needs of large-scale agricultural production. With its innovative technology and superior baling capabilities, the S9000 Classic excels in improving operational efficiency and reducing labor costs, and is widely used in farms, hay harvesting, and silage production. Its robust and durable design and high efficiency have made it the preferred equipment for many farmers.

9YG-2.24D Round Baler (S9000 Classic) Technical Specifications

For a clearer understanding of the product specifications, please find the detailed technical parameters below for your reference and model selections:

| No. | Item | Unit | Specification |

|---|---|---|---|

| 1 | Model Name | / | 9YG-2.24D Round Baler (S9000 Classic) |

| 2 | Hitch Type | / | Trailed |

| 3 | Pickup Width | mm | 2240 |

| 4 | Pickup Structure Type | / | Spring Tooth Type |

| 5 | Feeder Structure Type | / | Rake Root + Drum Type |

| 6 | Baling Chamber Structure Type | / | Drum Type |

| 7 | Baling Chamber Width | mm | 1400 |

| 8 | Baling Chamber Diameter | mm | φ1200 |

| 9 | Number of Rolling Components | pcs | 18 (Drum) |

| 10 | Rolling Drum Diameter | mm | φ222 |

| 11 | Binding Method | / | Net Wrap |

| 12 | Required Power | kw | 55-100 |

| 13 | Structural Weight | kg | 4312 |

| 14 | PTO Speed | r/min | 720 |

| 15 | Overall Dimensions (L×W×H) | mm | 4470×3010×2370 (Working State) |

| 16 | Bale Density Control | / | Sensor Control |

| 17 | Bale Size (Diameter × Width) | mm | φ1300×1400 |

| 18 | Bale Density | Kg/m³ | 100-200 |

| 19 | Productivity | bales/h | 40~100 |

| 20 | Wheel Track | mm | 2600 |

| 21 | Working Speed | Km/h | 5-35 |

| 22 | Net Specification (Length × Width) | / | 2000X1.4 meters/bale |

9YG-2.24D Round Baler (S9000 Classic) Core Advantages

1.9YG-2.24D Round Baler (S9000 Classic) – A compact and superior device

• The 9YG-2.24D Round Baler (S9000 Classic) features innovative crushing technology: employing a unique three-stage crushing + three-stage friction patented technology, and through an optimized cutting roller system and feeding mechanism, it optimizes the entire process from material pretreatment, fine crushing to final shaping. Field trials show that this technology can improve hay crushing uniformity by 40% and bale density consistency by 35%.

• The 9YG-2.24D Round Baler (S9000 Classic) features an extra-wide operating design: equipped with a 2240mm extra-wide pickup and a 5-35 km/h continuously variable transmission system, allowing a single machine to process 800-1200 bales per day, increasing efficiency by more than 50% compared to traditional models. Its unique roller-type compression chamber design ensures stable bale quality even at high speeds.• Intelligent Efficiency Optimization: A built-in operating efficiency monitoring system analyzes operating data in real time and automatically optimizes parameter settings, ensuring the equipment always operates under optimal conditions, effectively reducing unit operating energy consumption by 15-20%.

2. Superior Durability and Reliability

•Reinforced Structural Design: Key structural components utilize Q345B high-strength steel, achieving a fatigue life of over 1 million cycles. The compression chamber drum surface undergoes tungsten carbide spraying, increasing wear resistance by 3 times and extending service life to over 3000 working hours.

•Optimized Core Components: The transmission system employs heavy-duty bearings and hardened gears, validated through 2000 hours of accelerated life testing. The hydraulic system is equipped with a dual filtration system, ensuring reliability under harsh operating conditions.

•Ease of Maintenance: Modular design with centralized key maintenance points reduces daily maintenance time by 40%. Equipped with an intelligent diagnostic system, it can quickly locate fault points, reducing maintenance downtime.

3. Wide Adaptability

•All-Weather Operation Capability: Tested in environments ranging from -20℃ to 45℃, the hydraulic system and electronic components are designed for a wide temperature range, ensuring stable operation under extreme climatic conditions. Dust and water resistance reaches IP65, adapting to dusty and humid operating environments.

•Multi-material handling capacity: The optimized feeding system and adjustable density settings allow for perfect handling of various materials such as alfalfa, corn stalks, and rice/wheat straw, with particularly excellent performance in silage processing (moisture content 45%-65%).

•Strong terrain adaptability: Equipped with an automatic leveling system and a reinforced chassis, it maintains stable operation on complex terrains with slopes up to 15°. The 2600mm wheel track ensures excellent lateral stability.

4. Economic advantages

•Low operating costs:Optimized power matching and a high-efficiency transmission system reduce fuel consumption by 18-25% for the same workload. Long lifespan design and ease of maintenance significantly reduce maintenance costs.

•High return on investment: Based on actual user data, under standard operating conditions, the equipment’s investment payback period is typically 1.5-2 operating seasons, creating significant economic value for users.•High resale value: Thanks to its reliable quality and good market reputation, the equipment retains over 60% of its initial value in the resale market after 3 years of use.5. Environmental Protection and Safety.

•Environmental Compliance: Meets EU CE emission standards; noise levels are below 85 decibels; vibration levels comply with ISO standards, providing a comfortable working environment for operators.

•Safety Assurance: Equipped with multiple safety protection devices, including PTO overload protection, hydraulic system safety valves, and emergency stop buttons, ensuring the safety of equipment and personnel.

9YG-2.24D Round Baler (S9000 Classic) Product Highlights

1. Robust technology configuration, enabling efficient operation

The traction device employs a self-developed dual 10-inch drive shaft and innovatively adds a safety torque drive shaft. This not only effectively protects machine components but also specifically solves the problem of drive shaft jamming when turning in small plots, making operations in complex plots smoother. It allows for flexible turning on narrow field ridges or irregular plots, significantly improving work efficiency. The hydraulic system uses H-type compression joints, significantly improving pressure resistance and enabling faster opening and closing of the baling chamber for higher operating efficiency.

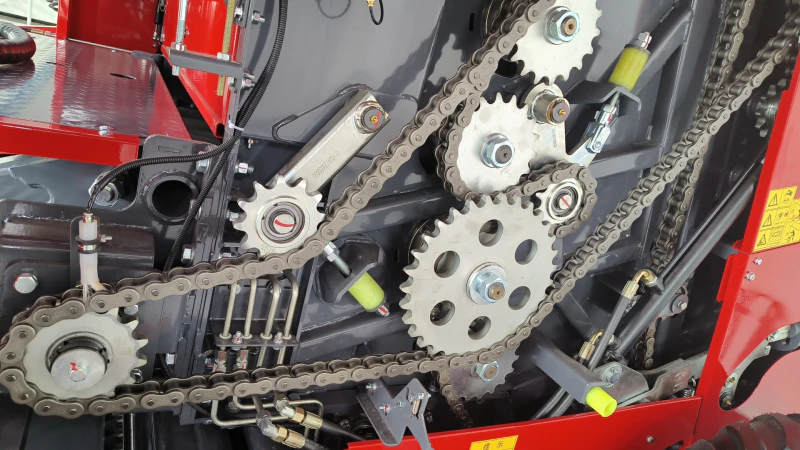

The rear baling chamber features a dedicated buffer cylinder design, effectively reducing impact damage caused by the baler’s closing vibration and extending the equipment’s service life. Simultaneously, the rear baling chamber is equipped with a heavy-duty gearbox and a dual-side sprocket drive structure, significantly improving the gearbox’s transmission torque and making the baling process smoother, fundamentally guaranteeing work quality and efficiency.

2. Superior performance proven in practical applications, renowned globally

With its superior performance, this product has been widely used in major agricultural areas of Northeast, North, and Northwest China, as well as international markets such as Australia and Russia, and has undergone rigorous testing in various environments. In large state-owned farms in Heilongjiang Province, a single unit can process over 15,000 bales annually with a availability rate exceeding 95%, fully meeting the needs of large-scale agricultural production. In a 45°C high-temperature ranch in New South Wales, Australia, the equipment demonstrated stable and continuous operation, and its excellent environmental adaptability has won high praise from international users.

3. Authoritative Certifications Guarantee Quality

As a national high-tech enterprise, the company has its own regional-level enterprise R&D center. Its products have passed ISO 9001 quality management system certification, ISO 14001 environmental management system certification, and information technology and industrialization integration (Level A) certification. The company has also been rated as an AAA-level credit enterprise and a trustworthy quality enterprise, achieving international advanced standards in both production and technology, providing reliable quality assurance to global users.

Compatible models and range

As a highly efficient and reliable piece of equipment for medium to large-scale farm operations, the 9YG-2.24D round baler (S9000) demonstrates its superior adaptability and powerful operational capabilities. This high-performance round baler is designed to meet the needs of modern large-scale agriculture, easily handling hay, wet hay, and various forages, making it an ideal choice for forage harvesting companies and silage producers. Its strong compatibility allows for seamless matching with tractors of various models and power, meeting diverse crop baling needs and becoming an indispensable key piece of equipment for improving agricultural productivity.

| Parameter | Specification |

|---|---|

| Model | 9YG-2.24D Round Baler (S9000 Classic) |

| Application | Medium to large farms, forage harvesting companies |

| Crop Compatibility | Dry grass, wet grass, pasture grass, various forage materials |

| Tractor Power | 55-100 kW (Compatible with multiple brands) |

| Productivity | 40-100 bales/hour |

Frequently Asked Questions (FAQ)

Q: Which farms is this equipment suitable for?

A: The 9YG-2.24D Round Baler (S9000 Classic) is suitable for medium to large farms, especially those requiring efficient harvesting and baling. It efficiently bales hay, wet hay, and silage.

Q: Is the equipment difficult to maintain?

A: This equipment features an easy-to-maintain design; regular cleaning and lubrication are sufficient. Main maintenance tasks include checking the hydraulic system, cleaning the pickup, and regularly replacing worn parts. Simple daily checks and lubrication can effectively extend the equipment’s lifespan.

Q: How to perform daily maintenance?

A: Daily maintenance includes cleaning the equipment, checking the hydraulic system, and lubricating all moving parts. It is also necessary to regularly check key components (such as the transmission system and rollers) to ensure their proper functioning. A detailed maintenance guide is included with the equipment; users can refer to it and perform maintenance on time.

Q: How do I choose the right model for my farm?

A: Choose the appropriate model based on factors such as farm size, crop type, and workload. If you are unsure, please contact our sales team and we will provide you with a customized equipment selection plan.

Related product – PTO shaft

The role of the PTO shaft in a round baler:

1. Providing core power

This is its most fundamental function. It directly transmits the rotational mechanical energy generated by the tractor engine to the gearbox of the round baler. Then, the gears, chains, or hydraulic system inside the round baler distribute this power and drive various working components, such as the pickup, the forming mechanism, and the hydraulic system.

2. Adaptability to Terrain and Steering

When a tractor-pulled round baler is operating in the field, the road surface is uneven and frequent turns are required. The PTO driveshaft is not a rigid iron bar; it consists of the following parts to adapt to complex working conditions:

• Universal Joints: Located at both ends of the shaft, they allow for smooth power transmission even when there is an angle between the driveshaft and the round baler, which is especially crucial when turning and going uphill/downhill.

• Telescopic Spline: The middle section of the driveshaft can extend and retract like a telescope. This allows the shaft length to adaptively adjust when the tractor turns or travels on uneven ground, causing slight changes in the distance between the two, preventing it from being bent or pulled off.

• Safety Devices: Modern PTO driveshafts are equipped with safety clutches or shear pins. When a blockage occurs inside the round baler (e.g., large stones or metal objects get caught), causing a sudden and sharp increase in load, the safety device disconnects power transmission, protecting the round baler’s gearbox, transmission system, and even the tractor’s PTO mechanism from serious damage. This is a very important protective function.

3. Ensuring ease of operation and versatility

The PTO interface is a standardized design (like the ISO series), allowing tractors of different brands to easily connect to round balers of different brands. Farmers simply insert and lock the PTO driveshaft to complete the power connection, which is very convenient.

If you are interested in our forage balers, please contact us for the latest quote.

Editor: WLB

Avis

Il n’y pas encore d’avis.