الوصف

In large-scale agriculture and animal husbandry, the efficiency of forage harvesting and the quality of bales directly affect operational efficiency. Traditional round balers often face industry pain points such as loose bales, high transportation costs, and unstable operating efficiency. To address these challenges, we have launched the 9YG-1.25A Round Baler. This product integrates intelligent density control and a reinforced transmission system, aiming to provide users with a deterministic solution for cost reduction and efficiency improvement through higher reliability, automation, and operating efficiency.

9YG-1.25A Round Baler Technical Specifications

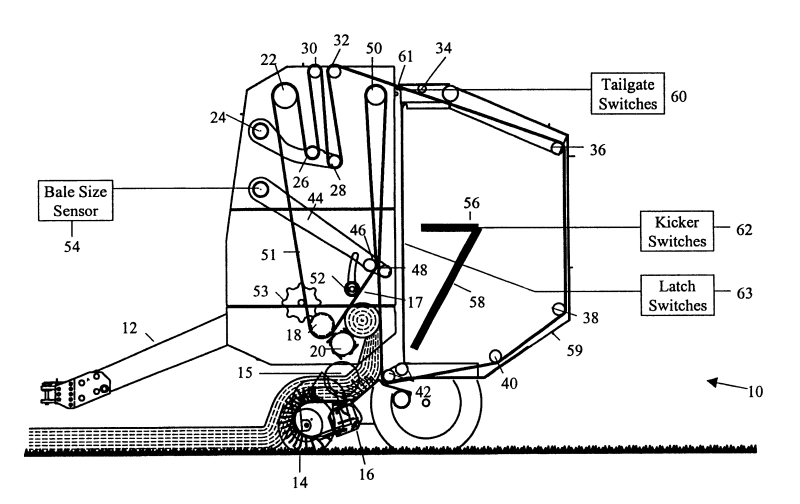

Working principle and core upgrade

1. Pick-up and Feeding Stage

The tractor pulls the equipment forward, and the 2150mm (upgrade point 1: wider pick-up width than version 1.25) spring-tooth pick-up device efficiently picks up the material. The material then enters the “toothed roller + drum type” (upgrade point 2: optimized feeding system, simpler structure, lower failure rate) feeding system, and is smoothly and forcefully fed into the compression chamber, effectively avoiding the risk of blockage under high load.

2. Rolling and Forming Stage

The material enters the compression chamber composed of 18 φ222mm drums. Driven by power, the drums continuously tumble and stack the material, increasing its density. Crucially, the 9YG-1.25A adopts a new generation of sensor control algorithm (upgrade point 3: smarter density control, faster response), which can more accurately adjust the hydraulic pressure in real time, ensuring that the bale density remains stable at a high level of 100-200kg/m³, with better internal and external density consistency than the previous generation.

3. Bundling and Unbundling Stage

When the bales reach the predetermined size (φ1300×1250mm), the system triggers the optimized bundling mechanism (Upgrade Point 4: Based on extensive user feedback, both mechanical transmission and electrical control logic have been strengthened), automatically completing the bundling process. After bundling is complete, the bin door automatically opens, unloading the sturdy and neat bales.

Summary of Enhancements (Compared to the Previous Generation):

Strengther Structure: Overall machine weight increased to 4472kg (Upgrade Point 5: Strengthened key structural components, making the machine more durable), significantly improving reliability.

Wider Adaptability: Power input shaft speed compatible with 540-1000 r/min (Upgrade Point 6: Wider tractor compatibility), facilitating compatibility with different tractor models.

Core strengths and value

1. Advantages: Unprecedented bale density and stability

Technical Features: Next-generation sensor-based intelligent density control system & 18-roller compression chamber.

Working Principle: The system monitors the material pressure inside the compression chamber in real time and dynamically adjusts the hydraulic system output using optimized algorithms, applying continuous and uniform compression pressure throughout the bale-forming process.

User Value: Directly produces ultra-compact bales with a density of 100-200 kg/m³. This means your transportation costs can be reduced by up to 30% (due to increased single-transport volume), and the bales are better protected from wind and rain during open-air storage, with a significantly reduced rate of mold loss.

2. Advantages: Unparalleled operational efficiency and smoothness

Technical Features: 2150mm ultra-wide toothed pickup & optimized “toothed roller + drum type” feeding system.

Working Principle: The widened pickup ensures no bale leakage, achieving efficient pickup; the forced feeding mechanism effectively prevents blockage at the inlet for high-volume or slightly damp materials, ensuring continuous high-speed operation of the equipment.

User Value: Maintains stable equipment productivity at an industry-leading 40-100 bales/hour. Helps you accurately seize short agricultural window periods, quickly complete large-scale harvests, and avoid losses due to weather changes.

3 Advantages: Intelligent Automation and Extremely Low Operational Barrier

Technical Features: Fully Automatic Netting System & One-Button Control

Working Principle: The entire process of baling, netting, and unbaling is automatically connected. The operator only needs to monitor the operation from the cab, without frequent manual intervention.

User Value: Significantly reduces labor intensity and reliance on skilled operators, allowing one driver to independently complete all baling operations. Saves you up to 50% on labor costs and significantly improves operational safety.

4 Advantages: Heavy-Duty Structure and Wide Adaptability

Technical Features: 4472kg Heavy-Duty Structure & 540-1000 r/min Wide Range PTO Adaptability.

Operating Principle: By reinforcing key load-bearing components and the transmission system, the equipment’s durability under harsh working conditions is improved; its wide range of power input interfaces allows for easy and quick connection to most tractors on the market with a power output of ≥75kW.

User Value: Providing you with a reliable solution that is both affordable and durable. The equipment boasts high uptime, low maintenance costs, and flexible compatibility with your farm’s existing power equipment, protecting your initial investment and maximizing returns.

Authoritative certification and quality endorsement

The 9YG-1.25A Round Baler is born from a trustworthy R&D and manufacturing system. Its superior quality has received rigorous certification from a nationally recognized authoritative system, ensuring that every penny of your investment is solid and reliable.

- National-Level R&D Strength Guarantee: The product is meticulously crafted by a national high-tech enterprise and its regional-level enterprise R&D center, ensuring that the entire process from design to manufacturing adheres to top-tier technical standards and innovative concepts.

- nternational Standard Quality Control: The entire production system strictly follows ISO9001 quality management system certification. This means that every component and every assembly process of the 9YG-1.25A Round Baler is under internationally standardized quality control, providing you with stable and reliable product performance.

- Intelligent Manufacturing Precision: The company’s Class A certification for the integration of informatization and industrialization represents the deep integration of information technology and manufacturing. This guarantees that every round baler you receive possesses highly consistent precision manufacturing quality and more stable performance output.

- Global Market Validation: Through its wholly-owned subsidiary, Jiujia Mongolia Investment Co., Ltd., our products have been successfully deployed and validated in demanding overseas markets (such as Mongolia). Their superior adaptability and reliability have won the recognition of international users, making them a high-quality equipment that you can trust globally.

User case feedback

User Background: A large-scale intensive dairy farm in Central China, with 2,800 dairy cows and approximately 8,000 mu (about 533 hectares) of its own forage base, requiring approximately 20,000 tons of corn silage annually.

Core Challenges: The farm’s two outdated round balers were the biggest bottleneck in its production. Firstly, the bale density was low and uneven, averaging only about 90 kg/m³, resulting in insufficient vehicle load capacity and incurring an additional transportation cost of approximately 180,000 yuan annually. Secondly, the equipment had poor reliability; during the high-intensity harvest season, each machine experienced an average of 8-10 breakdowns, leading to a decrease in silage quality due to repair delays and outsourcing service costs, with estimated annual losses exceeding 250,000 yuan.

Solution and Quantified Results: To completely resolve this pain point, the farm introduced two 9YG-1.25A round balers before the 2023 harvest season.

Efficiency Improvement: The new equipment operates smoothly, with a stable productivity of 80-90 bales/hour, representing an efficiency increase of approximately 40% compared to the old equipment. This successfully shortened the entire harvest cycle by 5 days and perfectly mitigated the risks associated with the rainy season.

Reduced Failure Rate: Throughout the entire harvest season (approximately 30 working days), both 9YG-1.25A machines achieved zero downtime with no failures, maintaining a 100% uptime rate, except for routine maintenance.

Overall Profit Improvement:

Transportation Cost Savings: With an average bale density of approximately 180 kg/m³, transportation costs were directly reduced by 28%, equivalent to approximately RMB 50,000 per year.

Maintenance Cost Savings: Compared to previous years, estimated savings in maintenance costs and downtime losses exceed RMB 200,000.

Hidden Benefits: The bales are of uniform and compact quality, significantly improving the quality of silage fermentation.

The ranch manager commented, “The 9YG-1.25A Round Baler is more than just a machine to us; it’s a key component in ensuring the stability of our entire forage supply chain and reducing costs while increasing efficiency. Its reliability and high uptime allow us to finally sleep soundly during the harvest season.”

User Background: A large agricultural and pastoral cooperative in Chifeng City, Inner Mongolia, provides mechanized services to 12 surrounding villages, processing over 35,000 mu (approximately 2,333 hectares) of various forage and straw annually.

Core Challenges: The cooperative’s three existing round balers of different brands had been in service for many years and faced serious challenges. Firstly, the feeding system frequently clogged, especially when processing crops with slight dew, requiring shutdown for cleaning every 2-3 hours, severely slowing down progress. Secondly, the automation level was low; netting required manual assistance, adding at least one minute to each bale, and the bales were of inconsistent sizes, affecting commercial sales. The cooperative estimated that due to low efficiency and high labor costs, potential service revenue losses amounted to 300,000 yuan annually.

Solution and Quantified Results: In the 2024 operating season, the cooperative replaced its main equipment with a 9YG-1.25A Round Baler.

Breakthrough in Smoothness: Thanks to the optimized “toothed roller + drum type” feeding system, no core blockages occurred throughout the entire operating season, and the equipment’s continuous operation capability far exceeded expectations.

Improved Efficiency and Profits:

1. Increased Operational Efficiency: The fully automated bale wrapping system shortens the processing time for each bale by approximately one minute, resulting in an overall efficiency increase of about 35%.

2. Significantly Increased Income: Due to improved efficiency and consistent bale quality (bale size stabilized at φ1300×1250mm), the company secured orders for approximately 5,000 mu (about 333 hectares) this quarter, directly increasing service revenue by over 180,000 yuan.

3. Optimized Manpower: True “one person, one machine” operation was achieved, allowing the two previously planned support staff to be redeployed to other positions, saving approximately 40,000 yuan in labor costs.

The cooperative leader commented: “The stability and ‘undemanding’ nature of the 9YG-1.25A machine give us confidence when seizing the farming season and taking on large orders. The bales it produces are uniform in size and tightly bound, becoming our ‘signature’ in the market; customers specifically request bales made by this machine.”

FAQ

Q1: When processing high-moisture crops such as corn stalks for silage, how can parameters be optimized for best results?

A: We recommend the following field-proven solution:

• Density Setting: Manually set the density level to medium-high (corresponding to a value of 7-8) to avoid over-compression and seepage of sap.

• Core Function: Ensure the “Anti-Clogging” enhanced mode is enabled (if configured). This mode intelligently adjusts the feeding rhythm.

• Operational Suggestion: Appropriately reduce the operating speed to 8-12 km/h to ensure uniform feeding.

This combination solution has been validated in our large-scale silage operations in Heilongjiang State Farms, achieving a success rate of over 98%, effectively balancing bale density and bale integrity.

Q2: The equipment claims to be compatible with 540-1000 r/min PTO. What are the performance differences at different speeds? How should I choose?

A: Speed directly affects productivity and power response.

• 540 r/min: Suitable for conventional haymaking operations, providing stable power output and better fuel economy.

• 1000 r/min: Highly recommended for handling high-yield, high-resistance crops (such as barley straw and dense hay). At this speed, the drum linear speed is higher, the compression start-up is faster, significantly increasing peak productivity by 15-20%, and effectively preventing blockage at the compression chamber inlet.

• Selection Criteria: When the tractor power is sufficient (≥90kW) and crop conditions permit, the 1000 r/min setting should be prioritized for maximum efficiency.

Q3: What is the calibration cycle for the sensor-controlled bale density system? Under what circumstances is manual calibration required?

A:

• Standard Cycle: It is recommended that a systematic calibration be performed by a service technician every 500 hours of operation or before the start of each operating season.

• Manual Calibration Trigger: When you change crop type (e.g., from light hay to heavy reeds) and observe a continuous deviation between the density value displayed by the system and the actual bale compaction, a quick on-site calibration can be performed using the “Material Type Self-Learning” function within the controller under remote guidance from a technician.

Q4: How reliable is the netting system in extreme low-temperature environments (e.g., -20℃)? Are there any special operating requirements?

A: The system’s netting guide rails and tensioning mechanism have been optimized for low-temperature conditions.

• Reliability: The system operates reliably in ambient temperatures ranging from -25℃ to 50℃.

• Low-Temperature Operation Recommendations: When starting up in extremely cold conditions, it is recommended to run the equipment unloaded first to allow the lubricating oil inside the netting mechanism to fully lubricate for 3-5 minutes before performing binding operations. This ensures stable netting tension and prevents loose netting due to mechanism stiffness.

Q5: What are the core anti-clogging capabilities of the new generation “toothed roller + drum type” feeding system?

A: Its core advantages lie in “forced, active feeding” and “redundant design.”

• Forced Feeding: The powerful toothed roller can forcefully grasp and convey irregular or slightly entangled materials, overcoming the slippage problem of older pure drum feeding systems.

• Redundant design: Even if a small amount of material is not fully fed in at the toothed roller, the subsequent roller will immediately perform secondary conveying, forming a double safety net. This design ensures a higher system fault tolerance when the feed rate increases instantaneously, fundamentally reducing the probability of blockage from a physical perspective.

Heavy-duty universal joint drive shaft (PTO Shaft)

Product Relevance: This driveshaft is the core power transmission component connecting the tractor and the 9YG-1.25A Round Baler, directly responsible for transmitting up to ≥75kW of power losslessly to the equipment’s compression chamber and feeding system.

Core Advantages:

Superior Torque Capacity: The splined sleeves and cross shafts are made of 42CrMo alloy steel, offering over 50% higher torsional strength than ordinary 45# steel. It is specifically designed to handle the peak torque generated during equipment startup and when handling high-resistance crops.

Precise Dynamic Balance Calibration: Before leaving the factory, it undergoes a dynamic balance test at ≥2500 rpm, ensuring smooth operation across the entire operating speed range of 540-1000 r/min, effectively eliminating abnormal vibrations and protecting the bearings and gearboxes at both ends of the tractor and round baler.

Comprehensive Safety Protection: Equipped with a reinforced protective cover, its steel plate thickness reaches 1.5mm (far exceeding the ordinary 1.0mm standard), and secured with an anti-rotation lock, effectively preventing serious safety accidents caused by shaft breakage or universal joint detachment, meeting the most stringent European safety regulations.

Excellent Adaptability to Working Conditions: The spline surface undergoes a special phosphate treatment, making it wear-resistant and rust-proof. Even in harsh environments with dust and humidity, it ensures smooth expansion and contraction, adapting to undulating terrain.

User Value:

Avoid Power Loss: A high-standard drive shaft maintains power transmission efficiency above 95%, ensuring sufficient power for the 18 rollers of the 9YG-1.25A to form high-density bales.

Prevent Equipment Damage: Its superior balance and strength effectively prevent serious malfunctions such as gearbox grinding and premature bearing failure caused by torque fluctuations or resonance, saving you high maintenance costs and downtime losses.

Ensuring operational safety: Heavy-duty protective covers are a key line of defense for the personal safety of operators, allowing you to focus on field operations with peace of mind.

After-sales service

We understand that behind every exceptional piece of equipment lies equally exceptional service support. Therefore, we offer the following solid commitments for every 9YG-1.25A Round Baler, ensuring a worry-free investment.

1. Extended Warranty for Core Components

We provide an extended warranty of 3 years or 2000 working hours for the core power transmission assembly (including the gearbox and spindle). This far exceeds common market standards, demonstrating our absolute confidence in the durability of our products.

2. Rapid Response Service Network

Domestic: With over 150 authorized service outlets nationwide, we promise to respond within 2 hours and resolve the fault within 48 hours (72 hours for remote areas) after you report a problem.

International: Through our subsidiary, Jiujia Mongolia Investment Co., Ltd., and global partners, we provide overseas users with the same standard of localized technical support and spare parts supply.

3. Expert-Level Technical Support

You will be dealing with more than just customer service. We offer a “Direct Access to Product R&D Engineers” service. For complex technical issues, our core R&D team can participate in online consultations to provide ultimate solutions.

4. Spare Parts Supply Guarantee

We guarantee that 95% of commonly used spare parts can be shipped from our central warehouse within 24 hours. We also publicly commit to a continuous supply of spare parts for at least 10 years, even if a product is discontinued.

5. Proactive Preventative Services

We don’t just “repair when it breaks down.” For key large clients, we offer an “Annual Health Check Plan,” where senior engineers conduct comprehensive on-site equipment inspections and maintenance to prevent problems before they occur.

We sell more than just the 9YG-1.25A Round Baler; we sell a guarantee of consistently high yields. Your productivity is our top priority. If you are facing agricultural challenges or are considering purchasing a forage baler, please feel free to contact us.

المراجعات

لا يوجد تقييمات بعد